Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

The process of specialty compounding uses melt-blended plastics with other additives as a means to achieve specific characteristics. Traditional compounding focuses on color matching, whereas specialty compounding adds different characteristics to the final plastic. In essence, specialty compounding changes the thermal, physical, electrical, and aesthetic characteristics of finished parts.

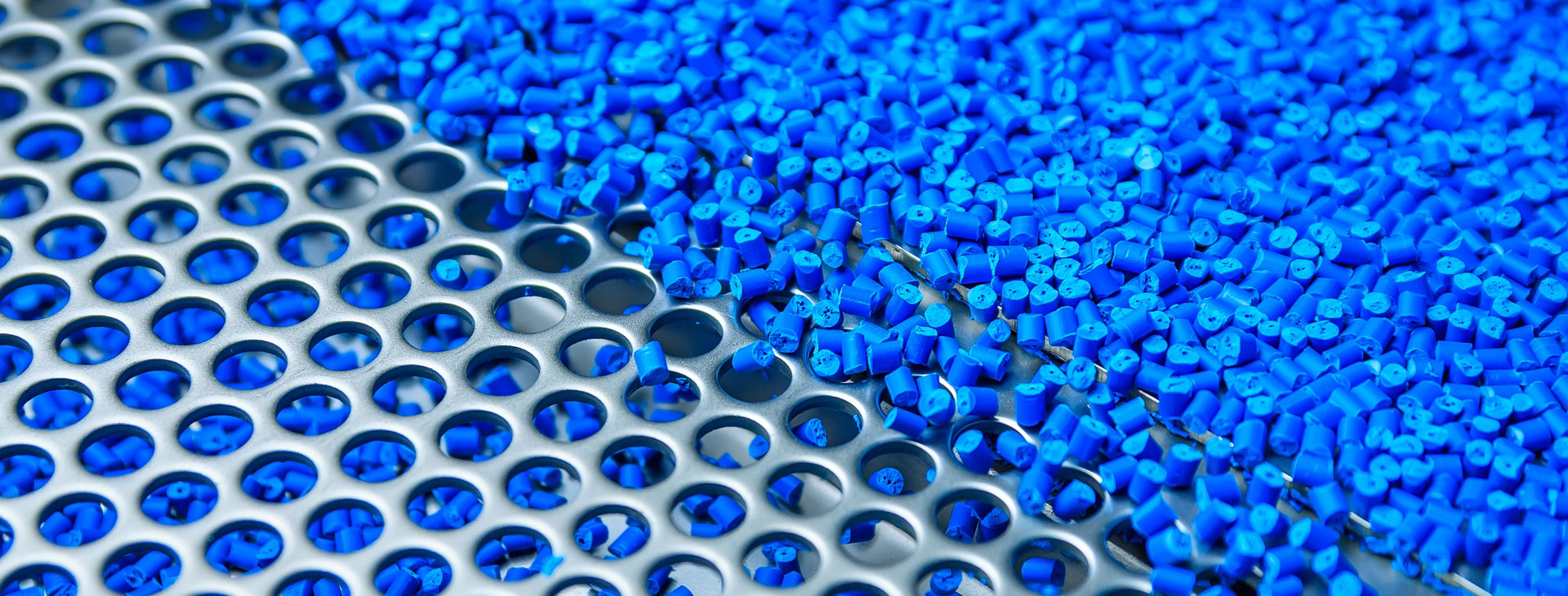

The first step in the process is to pick a polymer or base resin. After, reinforcers, additives, and fillers are added to give the final product desired properties. Both the resin and additives are lead into an extruder, where they come together. The batch then gets stretched into rope and cooled. After being cooled, they are cut into pellets. The final pellets are used in sheet extrusion or injection molding.

Typical characteristics that are available when using specialty compounding:

It is possible to add glass fibers to the extrusion process, which will increase the overall stiffness of the resins. We will help you and your company make smart decisions about specialty compounding. Give us a call, and we can help walk you through all your masterbatching needed. We are a trusted name in the resin distribution field.