Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

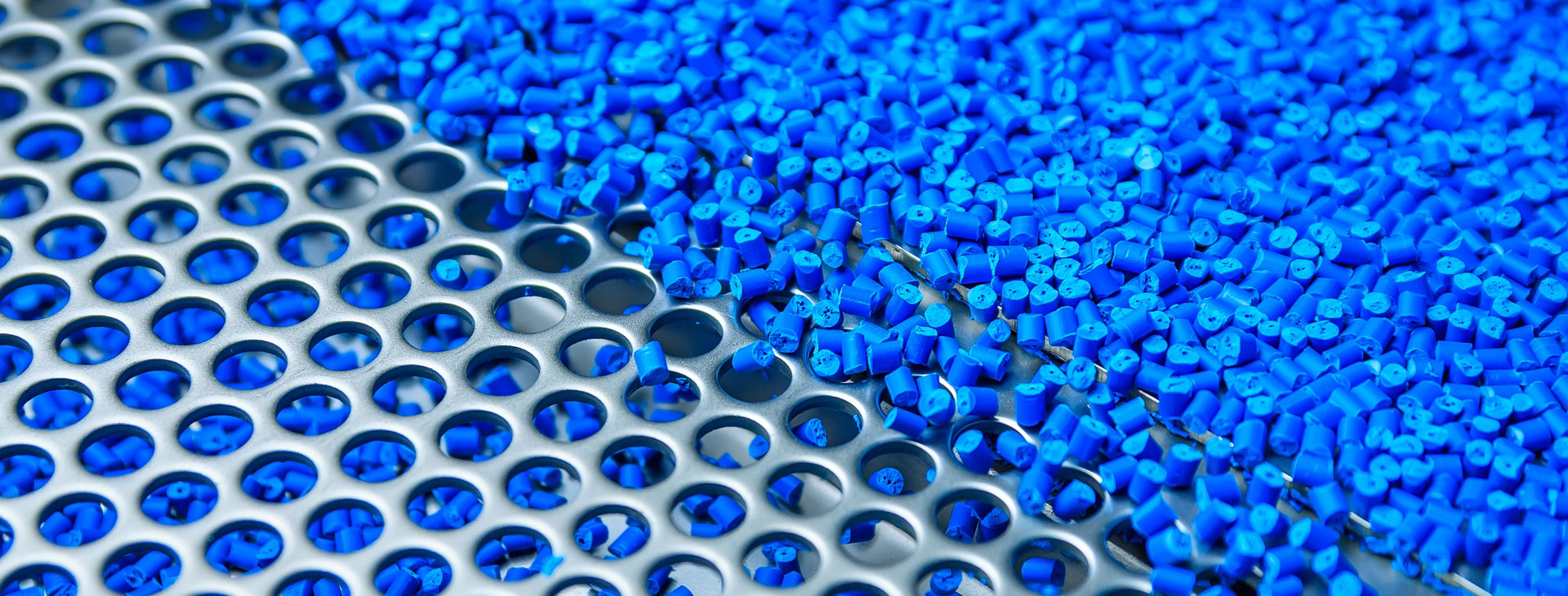

When dealing with synthetic resins, it is important to know the difference between different types. First, there are similarities shared between all synthetic resins. They are not too dissimilar from natural plant resins. This means that they have viscous liquids. These liquids are capable of hardening permanently. Besides this one connecting feature, the two resins are very chemically different.

When talking about synthetic resins, they are broken down in to a few separate classes. Different synthetic resins are created differently (by esterification and/or soaping of organic compounds). This is how different types of resins are created.

The most commonly used type of synthetic resin is epoxy resin. This stuff is made through polymerization and polycondensation reactions. They are used as a thermoset polymer that is used for adhesives. Epoxy resins are extremely strong. It is even stronger than concrete, while also remaining waterproof. You will most likely find flooring companies using this type of resin.

There is also something called synthetic casting resin. This is for embedding display objects in something like Plexiglas. This type of resin is known as a methyl methacrylate liquid. This liquid does not set by itself, and so a person needs to add a catalyst to the mix.

Acetal resin is another synthetic resin. When compared to other similar resins, one can see the simple chain structure. This resin is used to make parts that have a high stiffness, low friction, and amazing dimensional stability. You would find these materials most commonly used in the automotive and consumer electronic industry.

Industries that are working with water purification would most likely use ion exchange resin. This resin can also be used as a catalysis for organic reactions. There are even some cases of this resin being used in the pharmaceutical industry. They are used as hypolipidemic agents (this helps to lower cholesterol).

One other resin is called solvent impregnated resins. These resins are very porous, and there is extra liquid that accumulates in the holes. The purpose of this is to remove one or several of the dissolved components from a aqueous environment. The first instance of this resin was in 1971, and a man named Abraham Warshawsky created it. This resin is used to help recover heavy metals. This means they help to remove cadmium, vanadium, copper, and even chrome. Mostly you will find this resin being used in the biotechnology field.

Related Reading