Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

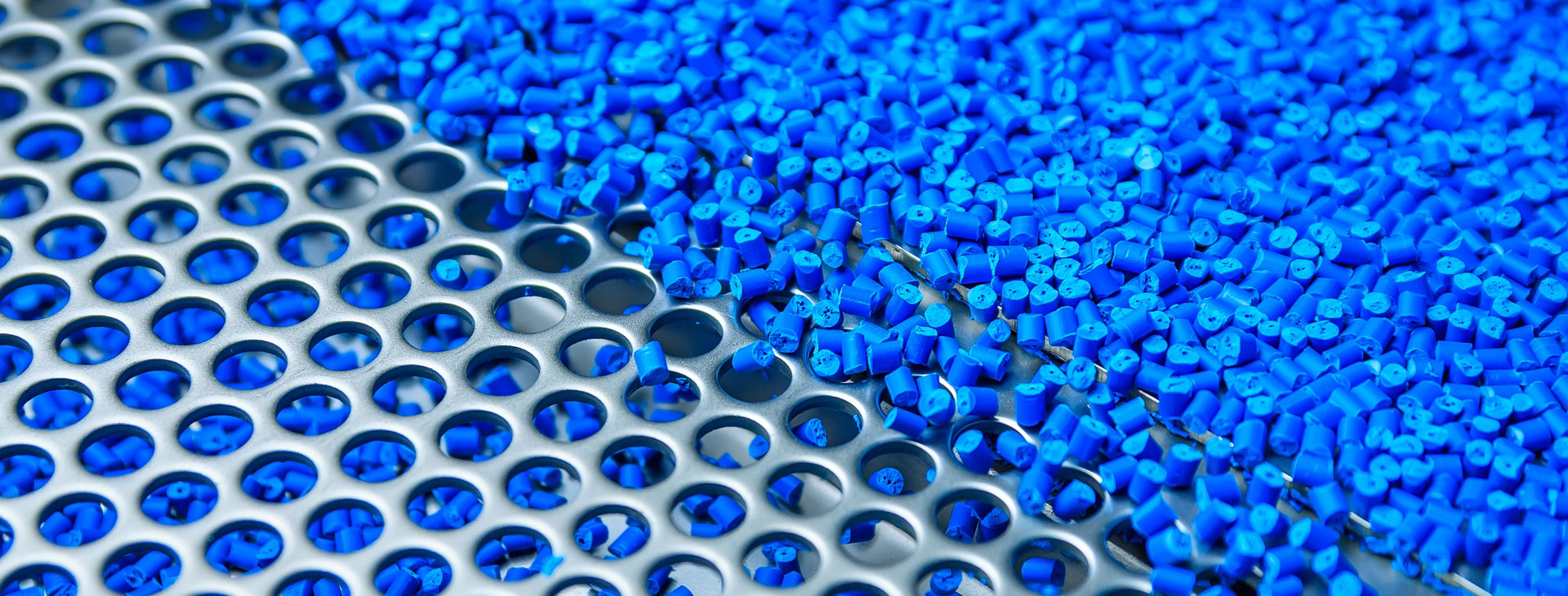

Thermoplastic compounds are polymers that are designed by manufacturers that blend different additives and colors during the plastic production process. Additives respond differently in various materials, which means that when the plastic sets, it will take on different characteristics. Specialty compounding plastic allows manufacturers to endow parts with specific colors and characteristics.

Common specialty compounding traits include:

Because of all the benefits compounding offers. It is commonly used in many industries.

Automotive makers commonly use compounding to build parts of their cars. Manufacturers add color resistance, impact resistance, and warping resistance to their plastics to make their vehicles better.

Builders also utilize specialty compounding. Everyday plastic products used include pipes, window profiles, siding, decks, and fencing. Each usage requires different compounds to perform optimally. UV resistance is common for home builders.

Consumer products also benefit from specialty compounding. Color enhancing and scratch resistance are two of the many compounds used in consumer products.

For any further questions, please do not hesitate to give our talented team a call.

Related Reading: