Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

Choosing between raw pigments and masterbatching can be somewhat tricky. Our modern world is covered in plastic products that are designed and colored with either masterbatching or pigments. Determining the right production method for your business will ensure vibrant, high-quality plastic. Raw pigments and masterbatching are similar, but they should not be used interchangeably. Each processing method has its pros and cons.

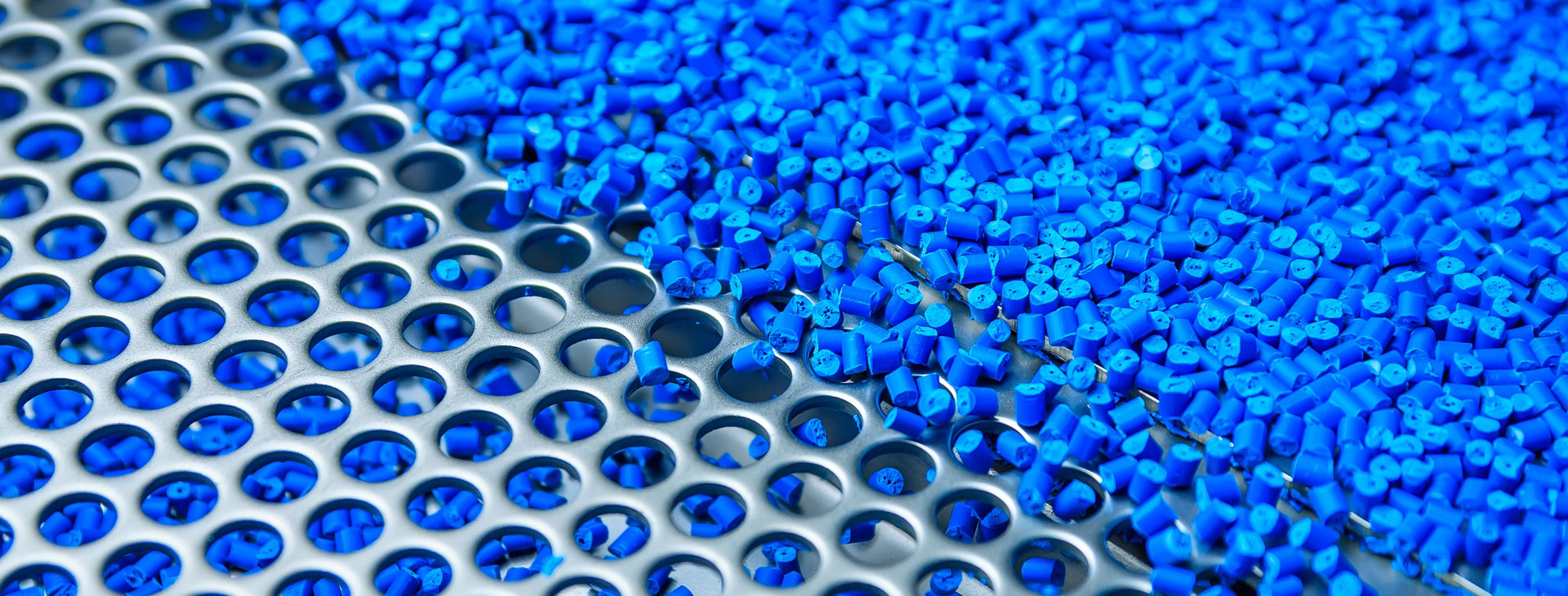

Raw pigments are solid and dry coloring substances, and during production, they are suspended in liquids to make dyes and paints. On the other hand, the masterbatching process requires specific concentrations of additives and pigments that are encapsulated with polymers. When comparing benefits of masterbatching to raw pigments, masterbatching tends to win out. Some of the most valuable benefits of masterbatching are:

There are other reasons to consider masterbatch besides the five above. For more information about this process, or specialty compounding in NY, let us be your first call. We can help you create beautifully colored plastic

Related Reading