Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

When it comes to producing colored plastics, many questions about the process arise. Of course, calling professionals with specific issues is an option, but it might turn out that your questions are commonplace. Below, we will be answering some frequently asked issues that consistently arise for profession masterbatch and resin distribution companies.

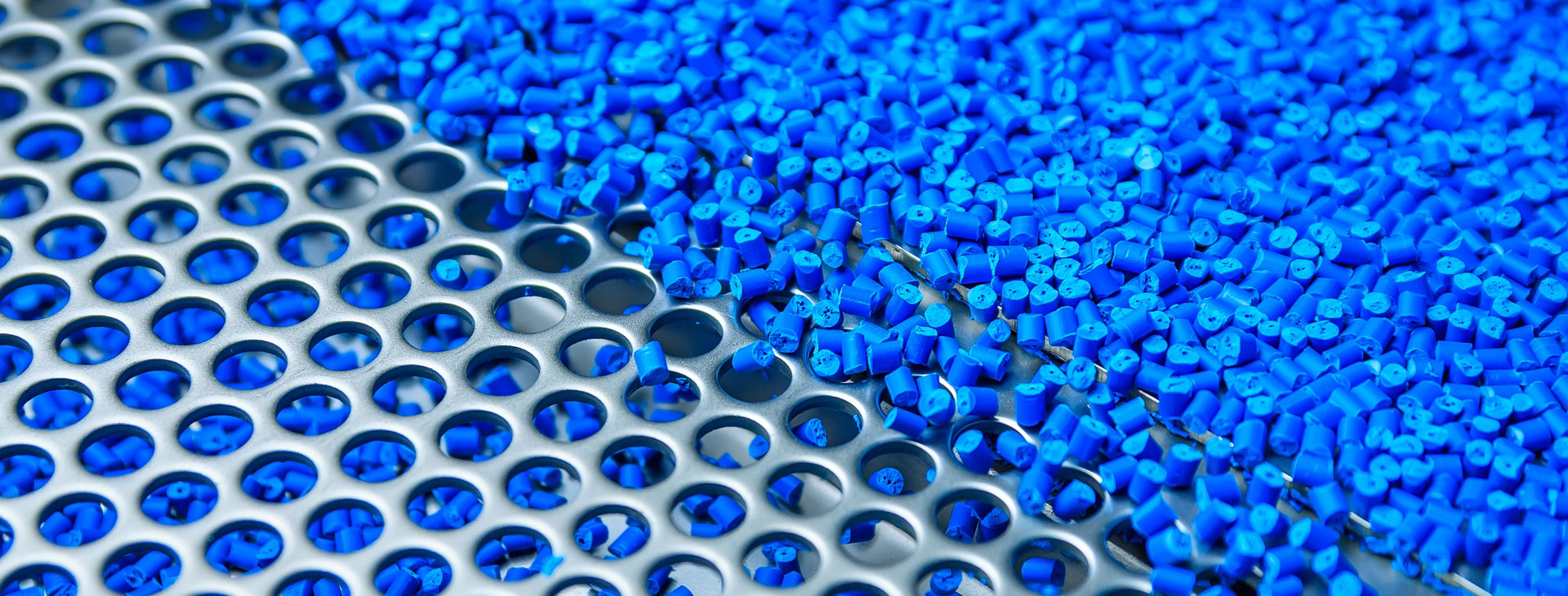

Many processes are used to color plastic, but the most cost-effective variant is masterbatching. This is the cause because natural polymers can be purchased in bulk. The process also benefits from a small obsolescence cost. Another cost saving aspect of the process is that there are fewer difficulties associated with final products.

With the help of computer programming, testing, and visual spot checking, any final color is achievable. Instruments are used to analyze the spectral data for each sample.

If you are dealing with a big business that has the proper infrastructure, it is possible to get color matches within one business week.

Any new piece of raw material is strictly inspected for quality control. Most raw materials are tested and that helps to ensure they will be able to handle the intended application.

If your questions about color masterbatch or resin distribution have not been completely answered, reach out for more help today!