Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

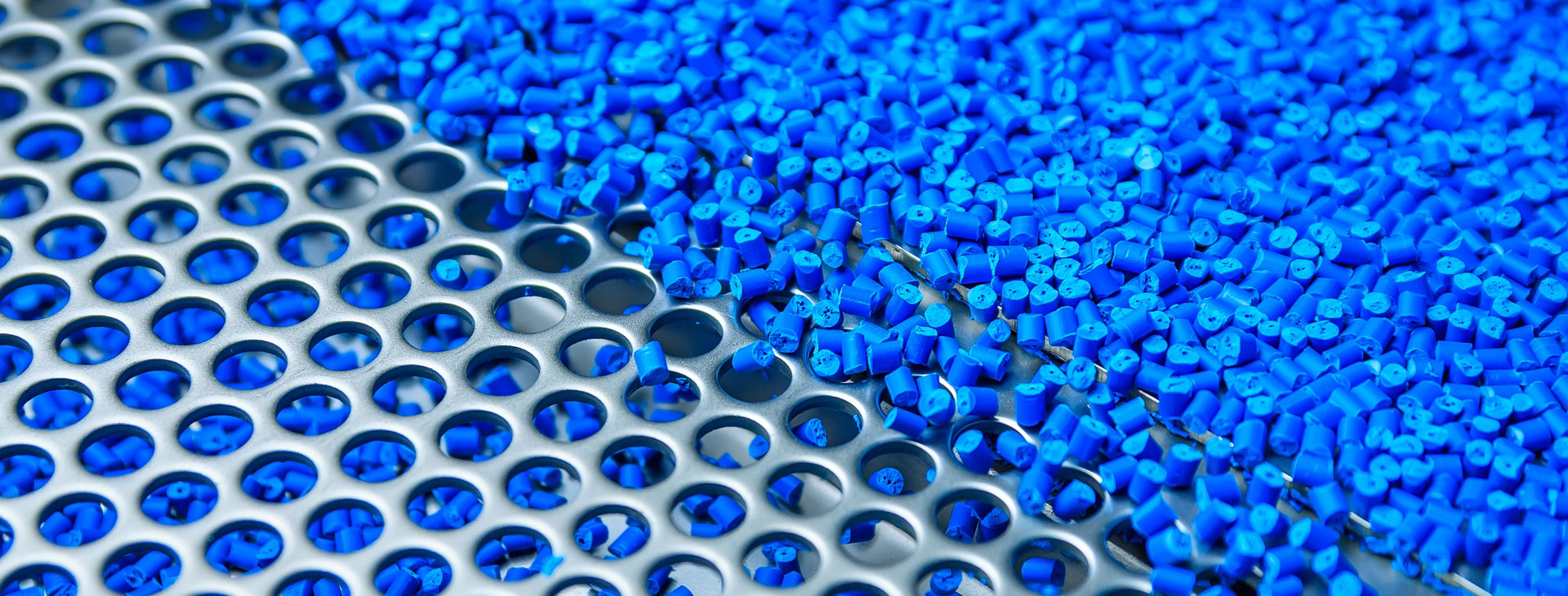

Specialty compounding is a manufacturing process that mixes creativity and science to create beautiful and practical plastic parts. We use modern technology to enhance base resins with reinforcements and additives. The end product is a unique material that meets strict aesthetic and performance criteria.

We use a wide range of different base polymers to meet the demands of our clients. Some of the most common base polymers we use include:

Polypropylene (PP): this polymer offers users a good balance of properties and low costs when compared to many other thermoplastics. The material is efficiently processed while maintaining strong chemical resistance.

Advantages

Limitations

Acetals (POM): this is a strong, rigid and creep resistant polymer. They boast low coefficients of friction. They are easily able to perform in high-temperature environments. Strong bases barely affect parts.

Advantages

Limitations

Polycarbonate (PC): this material maintains excellent impact strength, good dimensional stability, and high heat resistance. It is known as one of the first thermoplastics to offer these characteristics.

Advantages

Limitations

For more information on the full line of materials we use for specialty compounding in New York, you should not hesitate to give us a call.

Related Reading