Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

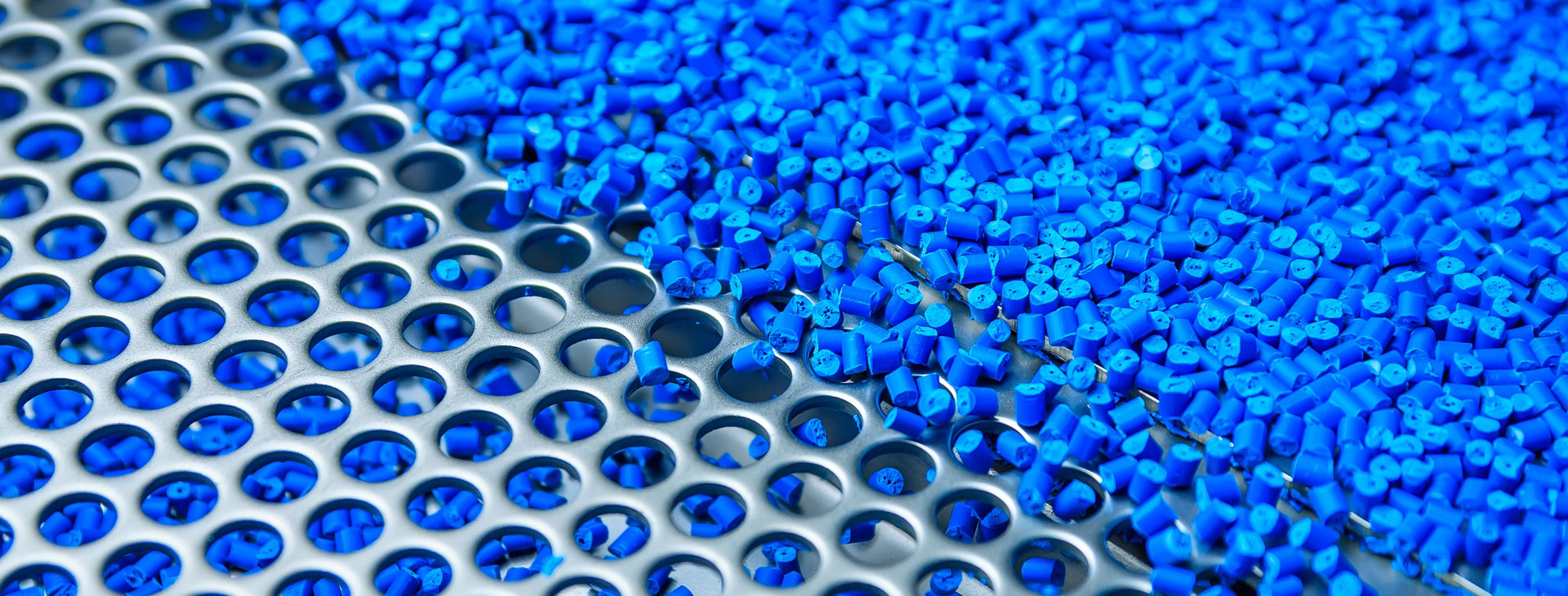

Plastic masterbatch consists of several properties that need modifying to suit specific applications. These are referred to as “functional” additives. They are developed to function in a unique way when added to a masterbatch or color masterbatch. When it comes to antistatic additives, there are certain things that are good to know.

Answer: Static electricity occurs when there is an imbalance of the molecular construction of relatively non-conductive insulators. One example of a non-conductive insulator is plastic. Static electricity is harmless to humans, but it can cost industries billions of dollars per year.

Answer: The main cause of static electricity is an unbalance of atoms. A “balanced” atom contains positive charges that are present in the nucleus of the atom. If there is an imbalance in the configuration of an atom, static electricity will occur.

Answer: Some examples of plastics are Polypropylene, PVC (Vinyl), Teflon, and Silicone. These materials have a tendency to collect electrons and become negatively charged.

Answer: The best way to avoid static electricity is the active method of static control called “ionization.” It’s impossible to get rid of static electricity completely. But it can be monitored when ionization is utilized.

Answer: Antistatic additives have static dissipative qualities that prevent static charges that build up on the surface of plastic products. While various antistatic sprays can be applied to the surface of parts, the excellent method of tackling this problem is through an antistatic additive that becomes an inherent part of the plastic material.

Answer: Many packaging applications use Antistatic Additives. This is because brand owners want the packaging to stay clear and shiny, and static in plastics can attract dust and dirt. The electronics industry uses Antistatic Additives a lot. Many electric and electrical assembly plants use carrier trays and totes molded from polymers with antistatic additives to prevent static build-up on the plastic carrier trays.