Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

It would be impossible to have specific cutting-edge medicine without the benefits provided by plastic. The material has outstanding flexibility that makes the material widely used in the medical technology field. Unlike other materials, plastic has easy processing, high fracture resistance, and low weight. It can be efficiently designed to meet the specific needs of the required profiles.

Products in the medical industry must meet an exceptionally high standard, which requires consistently strong qualities of raw materials. Medical instruments must meet the requirements of several quality boards.

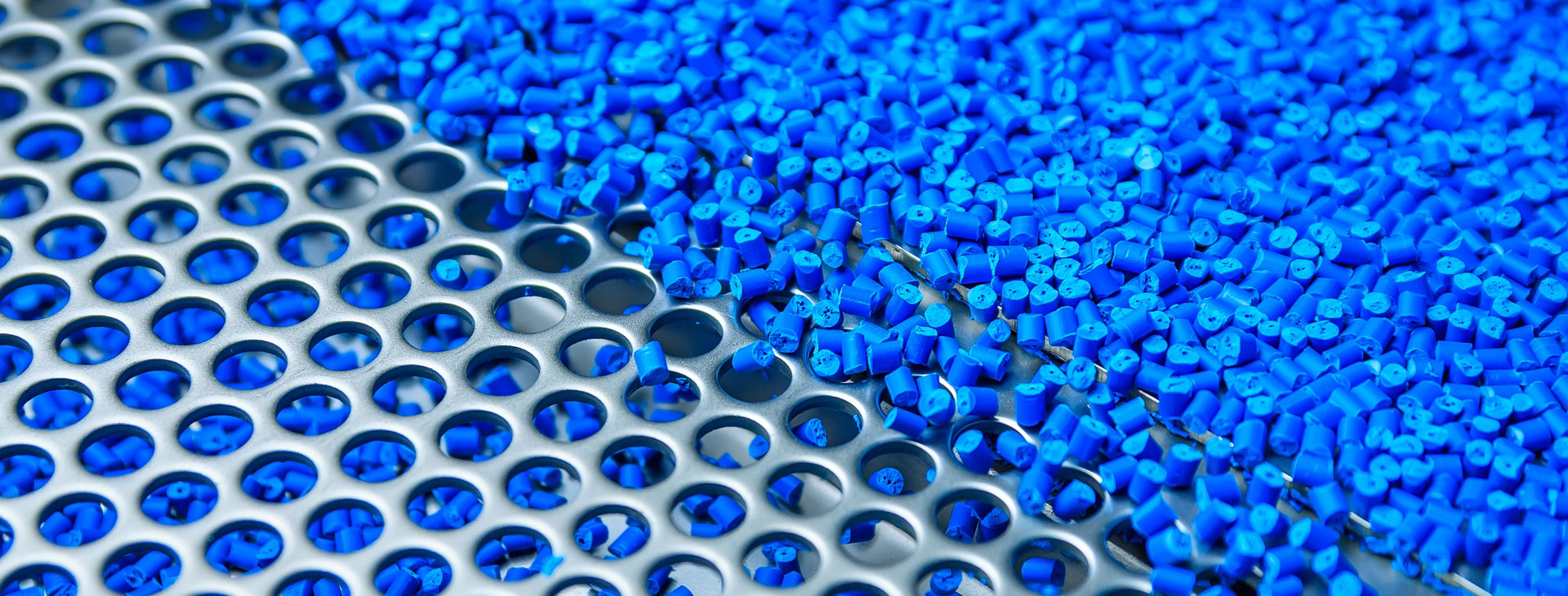

One commonly made plastic product for the medical industry is a needle holder. Color masterbatch allows for color coding of the plastic parts. International regulations require coloring to make pieces easily identifiable with only a glance. Color codes correlate with extra-thin, thin, and normal thickness of needles.

Specialty compounding of medical grade plastic is essential for product design. For instance, plastic parts must meet permanent antistatic qualities. Specialty compounding allows for plastic to increase the conductivity of polymers and to also reduce negative, partially charged states. This type of compounding also offers products in transparent colors, which helps to make safe handling and processing possible.

Flame-retardant additives also play a significant role in the creation of plastic parts for the medical industry. Our specialty compounding services in NY offers halogen-free, flame-retardant plastic.

We can help you bring your plastic medical equipment to life. For the best specialty compounding NY has, you should give us a call today.

Related Reading: